A cikin 'yan shekarun nan, tare da m amfani da graphite kyawon tsayuwa, da shekara-shekara amfani darajar da kyawon tsayuwa a cikin inji masana'antu ne 5 sau na jimlar darajar kowane irin inji kayayyakin aiki, da kuma babbar zafi asarar shi ne ma sosai saba wa data kasance makamashi-ceton manufofin a kasar Sin.The babban amfani da kyawon tsayuwa ba kawai kai tsaye ƙara kudin da Enterprises, amma kuma take kaiwa zuwa m samar da layi maye haddasa babbar hasara.

Bisa ga binciken, saboda mold albarkatun kasa da makamashi farashin ya tashi sosai da kuma wasu dalilai, da mold masana'antu ribar samfurin ya fadi a bara; Domin tsira da ci gaba, da yawa kamfanoni sun rungumi dabi'ar.

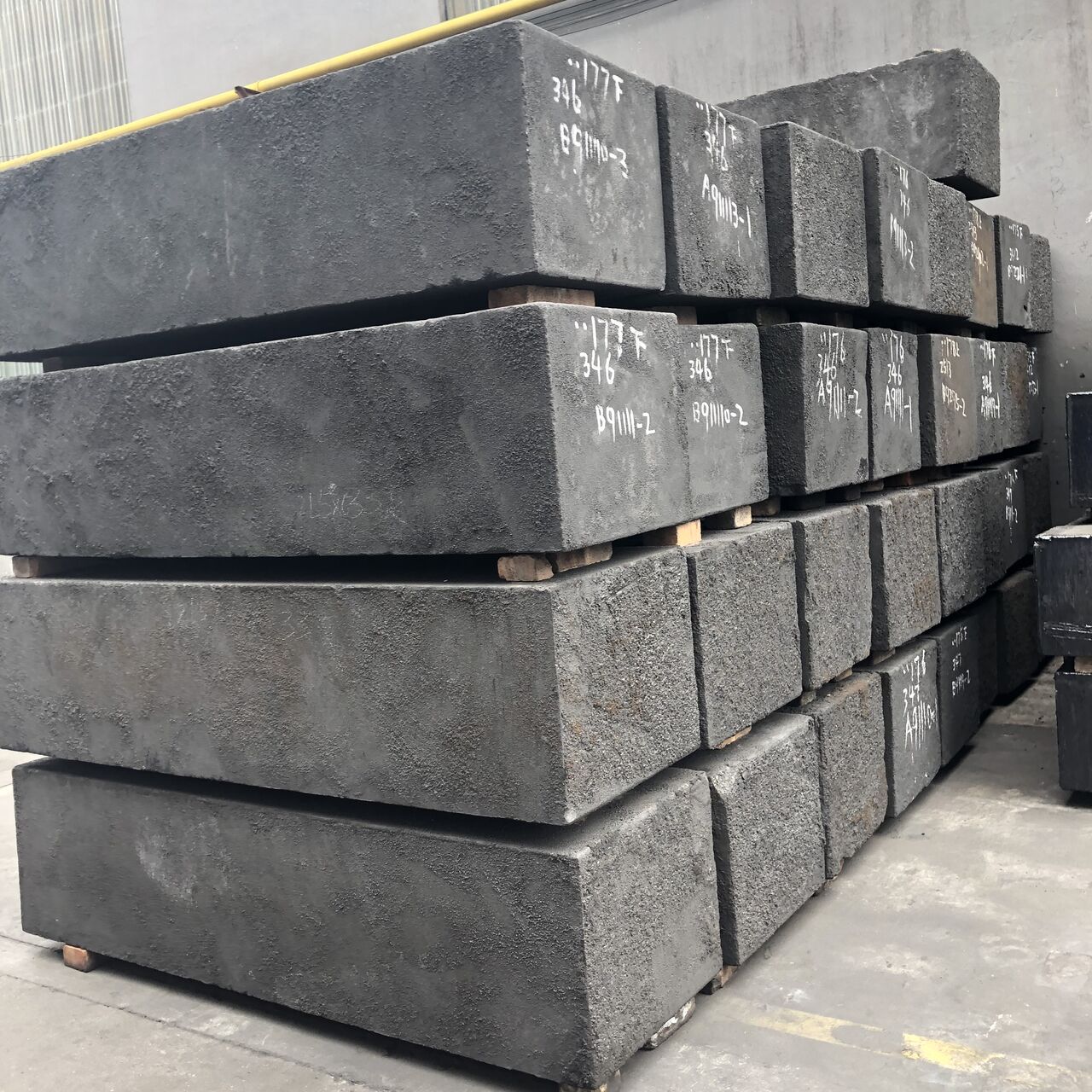

Material sauyawa da ake amfani da matsayin babban ma'auni na canji da kuma development.It an fahimci cewa da yawa kamfanoni kaddamar graphite walƙiya sallama kayan, a cikin mold samar da aka wasa da wani musamman muhimmanci role.Compared tare da gargajiya jan karfe mold, graphite abu yana da abũbuwan amfãni daga high machining daidaici da kyau surface sakamako, musamman a cikin mold kogon aiki na daidaici, hadaddun, bakin ciki bango da fa'ida, high graphite abu yana da babban fa'ida. rage yawan amfani, saurin fitarwa, nauyi mai haske da ƙananan haɓakar haɓakar thermal, don haka jan ƙarfe a hankali ya zama babban jigon kayan sarrafa fitarwa.Ya bambanta, kayan lantarki na graphite suna da fa'idodi guda shida masu zuwa:

1. Saurin sauri; Fitar da graphite shine sau 2-3 da sauri fiye da jan karfe, kuma kayan ba su da sauƙin lalacewa. Yana da fa'ida a bayyane a cikin sarrafa siriri ƙarfafa lantarki. Wurin laushi na jan karfe yana kusa da digiri 1000, kuma yana da sauƙin lalacewa saboda zafi.

2. Hasken nauyi; Yawan graphite shine kawai 1/5 na jan karfe. Lokacin da aka sarrafa babban lantarki ta hanyar fitarwa, za'a iya rage nauyin kayan aikin injin (EDM) yadda ya kamata, wanda ya fi dacewa da aikace-aikacen manyan ƙira.

3. Karamin almubazzaranci;Kamar yadda man walƙiya ya ƙunshi C atom, yawan zafin jiki yana haifar da ruɓar nau'in atom ɗin da ke cikin mai a lokacin sarrafa fitarwa, kuma an samar da wani fim mai kariya a saman na'urar lantarki na graphite, wanda ke rama asarar graphite electrode.

4. Babu burrs; Bayan an sarrafa wutar lantarki ta jan karfe, ana buƙatar cire burrs da hannu. Duk da haka, babu burrs bayan da aka sarrafa graphite, wanda ba wai kawai yana adana yawan farashi da ma'aikata ba, amma kuma ya sa ya fi sauƙi don gane samar da atomatik.

5. Easy polishing;Saboda yankan juriya na graphite ne kawai 1/5 na na jan karfe, shi ne sauki kara da goge da hannu.

Vi. Low cost;Saboda tashin farashin jan karfe a cikin 'yan shekarun nan, farashin graphite a duk fannoni ne m fiye da na copper.A karkashin wannan girma na Oriental carbon ta universality, farashin graphite kayayyakin ne 30% zuwa 60% m fiye da cewa na jan karfe, farashin ne in mun gwada da barga, da kuma gajeren lokaci farashin hawa da sauka ne in mun gwada da kananan.Tare da makamashi kiyayewa da kuma mayar da hankali masana'antu, da mayar da hankali efficite masana'antu. Kayan lantarki za su maye gurbin jan ƙarfe na jan ƙarfe a hankali kuma suna taka muhimmiyar rawa a cikin EDM. Hakazalika, a cikin ƙarar gasa mai tsanani a cikin kasuwar mold a yau, yin amfani da fasahar sarrafa kayan aiki don haɓaka samfurori masu inganci shine hanya mafi kyau ga kamfanoni don cin nasara kasuwa da abokan ciniki.

Lokacin aikawa: Maris-10-2021