1.EDM halaye na kayan graphite.

1.1.Fitar da saurin injina.

Graphite wani abu ne wanda ba na ƙarfe ba tare da babban wurin narkewa na 3, 650 ° C, yayin da jan ƙarfe yana da wurin narkewa na 1, 083 ° C, don haka graphite lantarki zai iya jure yanayin saitin yanzu.

Lokacin da fitarwa yankin da sikelin na lantarki size ne mafi girma, da abũbuwan amfãni daga high dace m machining na graphite abu ne mafi bayyananne.

Thermal conductivity na graphite shine 1/3 na jan karfe, kuma za'a iya amfani da zafin da ake samu yayin aikin fitarwa don cire kayan ƙarfe da kyau. Sabili da haka, ingantaccen aiki na graphite ya fi na jan ƙarfe na jan ƙarfe a cikin matsakaici da aiki mai kyau.

Dangane da ƙwarewar sarrafawa, saurin sarrafa fitarwa na lantarki na graphite yana da sauri sau 1.5 ~ 2 fiye da na jan ƙarfe a ƙarƙashin ingantattun yanayin amfani.

1.2.Yin amfani da Electrode.

Graphite lantarki yana da halin da zai iya jure wa high halin yanzu yanayi, a Bugu da kari, a karkashin yanayin da ya dace roughing saitin, ciki har da carbon karfe workpieces samar a lokacin machining kau a cikin abun ciki da kuma aiki ruwa a high zafin jiki bazuwar na carbon barbashi, da polarity sakamako, a karkashin mataki na m cire a cikin abun ciki, carbon barbashi za su manne da lantarki surface don samar da wani m Layer, ko da graphite hasãra, tabbatar da a cikin kananan graphite asara. banza”.

Babban hasara na lantarki a cikin EDM ya fito ne daga mashin injin. Ko da yake yawan asarar yana da yawa a yanayin saitin kammalawa, asarar gaba ɗaya kuma ta yi ƙasa sosai saboda ƙaramin izinin injin ɗin da aka tanada don sassa.

Gabaɗaya, asarar graphite electrode bai kai na jan ƙarfe na jan ƙarfe ba a cikin mashin ɗin na'ura mai girma da ɗanɗano fiye da na jan ƙarfe na jan ƙarfe a kammala aikin. Rashin wutar lantarki na graphite lantarki yana kama da haka.

1.3.The surface quality.

A barbashi diamita na graphite abu kai tsaye rinjayar da surface roughness na EDM. Karamin diamita shine, ana iya samun ƙananan ƙarancin ƙasa.

Bayan 'yan shekaru da suka wuce ta amfani da barbashi phi 5 microns a diamita graphite abu, mafi kyau surface iya kawai cimma VDI18 edm (Ra0.8 microns), a zamanin yau da hatsi diamita na graphite kayan sun sami damar cimma a cikin 3 microns na phi, mafi kyau surface iya cimma barga VDI12 edm (Ra0.4 mu m) ko fiye da sophisticed Electrode matakin.

Kayan jan ƙarfe yana da ƙarancin juriya da ƙarancin tsari, kuma ana iya sarrafa shi da ƙarfi a ƙarƙashin yanayi mai wahala. Tsawon saman na iya zama ƙasa da Ra0.1 m, kuma ana iya sarrafa shi ta madubi.

Don haka, idan injin ɗin fitarwa ya bi ƙasa mai kyau sosai, ya fi dacewa a yi amfani da kayan jan ƙarfe azaman lantarki, wanda shine babban fa'idar lantarki ta jan ƙarfe akan graphite electrode.

Amma jan karfe lantarki a karkashin yanayin babban halin yanzu saitin, da lantarki surface ne sauki zama m, bayyana ko da crack, da kuma graphite kayan ba zai sami wannan matsala, da surface roughness bukata VDI26 (Ra2.0 microns) game da mold aiki, ta yin amfani da graphite lantarki za a iya yi daga m zuwa lafiya aiki, gane uniform surface sakamako, da surface lahani.

Bugu da kari, saboda daban-daban tsarin na graphite da kuma jan karfe, surface fitarwa lalata batu na graphite electrode ya fi na yau da kullum fiye da na jan karfe electrode. Saboda haka, a lokacin da wannan surface roughness na VDI20 ko sama da ake sarrafa, da surface granularity na workpiece sarrafa ta graphite lantarki ne mafi bambanta, da kuma wannan hatsi surface sakamako ne mafi alhẽri daga fitarwa surface sakamako na jan karfe lantarki.

1.4. Daidaiton mashin ɗin.

Matsakaicin haɓakar haɓakar thermal na graphite abu kaɗan ne, ƙimar haɓakar haɓakar tagulla na kayan jan ƙarfe shine sau 4 na kayan graphite, don haka a cikin sarrafa fitarwa, graphite lantarki ba shi da kusanci ga nakasawa fiye da na'urar jan ƙarfe, wanda zai iya samun ƙarin kwanciyar hankali da amincin aiki daidai.

Musamman lokacin da ake sarrafa haƙarƙari mai zurfi da kunkuntar, yawan zafin jiki na gida yana sa lantarki na jan karfe lanƙwasa cikin sauƙi, amma graphite electrode ba ya.

Don na'urar lantarki ta jan ƙarfe tare da babban girman diamita mai zurfi, ya kamata a rama wani ƙimar faɗaɗa zafin zafi don gyara girman yayin saitin mashin ɗin, yayin da ba a buƙatar lantarki mai graphite.

1.5.Electrode nauyi.

Kayan graphite bai da yawa fiye da jan ƙarfe, kuma nauyin graphite electrode na wannan ƙarar shine kawai 1/5 na na jan ƙarfe.

Ana iya ganin cewa yin amfani da graphite ya dace sosai ga lantarki tare da babban girma, wanda ya rage girman nauyin kayan aiki na kayan aikin EDM. Electrode ba zai haifar da rashin jin daɗi a cikin matsewa ba saboda girman girmansa, kuma zai haifar da rarrabuwar kawuna a cikin sarrafawa, da dai sauransu. Ana iya ganin cewa yana da matuƙar mahimmanci don amfani da graphite electrode a cikin babban sikelin ƙirar ƙira.

1.6.Wahalhalun masana'antar Electrode.

Ayyukan machining na kayan graphite yana da kyau. Juriyar yankan shine kawai 1/4 na jan karfe. A ƙarƙashin ingantattun yanayin sarrafawa, ingancin milling graphite electrode shine sau 2 ~ 3 na jan ƙarfe.

Graphite lantarki yana da sauƙi don share kusurwa, kuma ana iya amfani dashi don aiwatar da aikin aikin wanda ya kamata a gama ta hanyar lantarki da yawa a cikin lantarki guda ɗaya.

A musamman barbashi tsarin na graphite abu hana burrs daga faruwa bayan electrode milling da kafa, wanda zai iya kai tsaye saduwa da buƙatun amfani a lokacin da burrs ba a sauƙaƙe cire a cikin hadaddun tallan kayan kawa, don haka kawar da aiwatar da manual polishing na lantarki da kuma guje wa siffar canji da girman kuskure lalacewa ta hanyar polishing.

Ya kamata a lura cewa, saboda graphite yana tara ƙura, graphite milling zai haifar da ƙura mai yawa, don haka injin milling dole ne ya sami hatimi da na'urar tattara ƙura.

Idan ya zama dole a yi amfani da edM don sarrafa graphite electrode, aikinsa ba shi da kyau kamar kayan jan karfe, saurin yankewa kusan 40% hankali fiye da jan karfe.

1.7.Electrode shigarwa da amfani.

Kayan zane yana da kyawawan kayan haɗin gwiwa. Ana iya amfani da shi don haɗa graphite tare da ƙayyadaddun ta hanyar niƙa lantarki da fitarwa, wanda zai iya adana tsarin mashin ɗin dunƙule rami akan kayan lantarki da adana lokacin aiki.

Abun graphite yana da ɗan tsinkewa, musamman ƙarami, kunkuntar da tsayin lantarki, wanda ke da sauƙin karyewa lokacin da aka yi amfani da shi daga waje, amma nan da nan zai iya sanin cewa wutar lantarki ta lalace.

Idan kuma tagulla ce ta wutan lantarki, sai kawai ta lanƙwasa ba ta karye, wanda ke da hatsarin gaske kuma yana da wahala a same shi a cikin tsarin amfani da shi, kuma cikin sauƙi zai kai ga guntun kayan aikin.

1.8.Farashi.

Kayan jan ƙarfe shine albarkatun da ba za a iya sabuntawa ba, yanayin farashin zai zama mafi tsada kuma yana da tsada, yayin da farashin kayan graphite yana ƙoƙarin daidaitawa.

Copper abu farashin tashi a cikin 'yan shekarun nan, da manyan masana'antun na graphite inganta tsari a cikin samar da graphite yin ta m amfani, yanzu, a karkashin wannan girma, generality na graphite lantarki abu farashin da farashin jan karfe lantarki kayan ne quite, amma graphite iya cimma m aiki, fiye da yin amfani da jan karfe lantarki domin ya ceci babban adadin aiki hours, daidai farashin kai tsaye don rage samar da.

Don taƙaitawa, a cikin halayen 8 edM na graphite electrode, fa'idodinsa a bayyane suke: ingancin injin milling da sarrafa fitarwa ya fi na jan ƙarfe; babban na'urar lantarki yana da ƙananan nauyi, kwanciyar hankali mai kyau, na'urar lantarki na bakin ciki ba ta da sauƙi don lalacewa, kuma rubutun saman ya fi jan karfe.

Rashin hasara na kayan graphite shine cewa bai dace da kyakkyawan aikin fitarwa na ƙasa a ƙarƙashin VDI12 (Ra0.4 m), kuma ingancin amfani da edM don yin lantarki yana da ƙasa.

Duk da haka, daga mahangar aiki, daya daga cikin muhimman dalilan da suka shafi ingantaccen tallan kayan graphite a kasar Sin, shi ne cewa ana bukatar injin sarrafa graphite na musamman don niƙa lambobi, wanda ke gabatar da sabbin buƙatu don sarrafa kayan aikin masana'antar ƙila, wasu ƙananan masana'antu na iya samun wannan yanayin.

Gabaɗaya, fa'idodin na'urorin lantarki na graphite sun rufe mafi yawan lokutan sarrafa edM, kuma sun cancanci yaɗawa da aikace-aikace, tare da fa'idodi na dogon lokaci. Ana iya samun ƙarancin sarrafa saman ƙasa ta hanyar amfani da na'urorin lantarki na jan karfe.

2.Zaɓi kayan lantarki na graphite don EDM

Don kayan graphite, akwai galibin alamomi huɗu masu zuwa waɗanda ke ƙayyade aikin kayan kai tsaye:

1) Matsakaicin diamita na abu

Matsakaicin diamita na abu yana shafar yanayin fitarwa na kayan kai tsaye.

Karami matsakaicin barbashi na kayan graphite shine, yawan fitowar uniform, mafi kwanciyar hankali yanayin fitarwa shine mafi kyawun ingancin saman, kuma ƙarancin asarar shine.

Ya fi girma da matsakaicin barbashi size ne, da mafi alhẽri kau kudi za a iya samu a m machining, amma surface sakamako na karewa ne matalauta da lantarki asarar ne manyan.

2) Ƙarfin lanƙwasawa na abu

Ƙarfin gyare-gyare na kayan aiki shine nunin kai tsaye na ƙarfinsa, yana nuna ƙaddamar da tsarinsa na ciki.

Kayan da ke da ƙarfi mai ƙarfi yana da kyakkyawan aikin juriya na fitarwa. Don na'urar lantarki tare da madaidaicin madaidaici, kayan da ke da ƙarfi ya kamata a zabar su kamar yadda zai yiwu.

3) Taurin bakin ruwa na kayan

Graphite yana da wuya fiye da kayan ƙarfe, kuma asarar kayan aikin yanke ya fi na yankan ƙarfe.

A lokaci guda, babban taurin kayan graphite a cikin sarrafa asarar fitarwa ya fi kyau.

4) Ƙaƙƙarfan tsayayyar abu

Yawan fitarwa na kayan graphite tare da babban juriya na asali zai kasance a hankali fiye da wancan tare da ƙarancin juriya.

Mafi girman juriya na asali, ƙananan asarar lantarki, amma mafi girma da tsayayyar mahimmanci, kwanciyar hankali na fitarwa zai shafi.

A halin yanzu, akwai nau'o'i daban-daban na graphite da ake samu daga manyan masu samar da graphite na duniya.

Gabaɗaya bisa ga matsakaita diamita na graphite kayan da za a classified, barbashi diamita ≤ 4 m aka bayyana a matsayin lafiya graphite, barbashi a 5 ~ 10 m aka bayyana a matsayin matsakaici graphite, barbashi a 10 m sama an ayyana a matsayin m graphite.

Ƙananan ƙananan diamita shine, mafi tsada kayan shine, mafi dacewa kayan graphite za a iya zaɓar bisa ga buƙatun da farashin EDM.

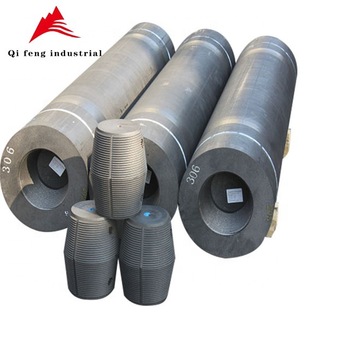

3.Fabrication na graphite lantarki

An fi yin graphite lantarki ta hanyar milling.

Ta fuskar fasahar sarrafawa, graphite da tagulla abubuwa ne daban-daban guda biyu, kuma ya kamata a ƙware da halayen yankansu daban-daban.

Idan graphite electrode aka sarrafa ta hanyar jan karfe electrode, babu makawa matsaloli za su faru, kamar karaya akai-akai na takardar, da bukatar yin amfani da dace yankan kayan aikin da yankan sigogi.

Machining graphite lantarki fiye da jan karfe lantarki kayan aiki lalacewa, a kan tattalin arziki la'akari, da zabi na carbide kayan aiki ne mafi tattali, zabi lu'u-lu'u shafi kayan aiki (wanda ake kira graphite wuka) farashin ya fi tsada, amma lu'u-lu'u shafi kayan aiki tsawon sabis rayuwa, high aiki daidaici, da overall tattalin arziki amfanin ne mai kyau.

Girman kusurwar gaba na kayan aiki kuma yana rinjayar rayuwar sabis ɗinsa, 0 ° kusurwar gaba na kayan aiki zai kasance har zuwa 50% sama da 15 ° na gaba na rayuwar sabis na kayan aiki, yankan kwanciyar hankali kuma ya fi kyau, amma mafi girman kusurwar, mafi kyawun machining surface, yin amfani da 15 ° Angle na kayan aiki zai iya cimma mafi kyawun machining surface.

The yankan gudun a cikin machining za a iya gyara bisa ga siffar da lantarki, yawanci 10m / min, kama da machining na aluminum ko filastik, da yankan kayan aiki na iya zama kai tsaye a kan kuma kashe workpiece a m machining, da kuma sabon abu na Angle rushewa da fragmentation ne sauki faruwa a kammala machining, da kuma hanyar haske wuka azumi tafiya ne sau da yawa soma.

Graphite lantarki a cikin yankan tsari zai samar da ƙura mai yawa, don kauce wa graphite barbashi inhaled inji sandal da dunƙule, akwai biyu main mafita a halin yanzu, daya shi ne don amfani da graphite sarrafa na'ura, da sauran shi ne talakawa aiki cibiyar refit, sanye take da wani musamman kura tarin na'urar.

The musamman graphite high gudun milling inji a kasuwa yana da high milling yadda ya dace da kuma iya sauƙi kammala masana'anta na hadaddun lantarki tare da high daidaici da kyau surface quality.

Idan ana buƙatar EDM don yin graphite electrode, ana ba da shawarar yin amfani da kayan graphite mai kyau tare da ƙaramin diamita.

A machining yi na graphite ne matalauta, da karami da barbashi diamita ne, da mafi girma da yankan yadda ya dace za a iya samu, da kuma m matsaloli kamar m waya karya da surface Geza za a iya kauce masa.

4.EDM sigogi na graphite lantarki

Zaɓin sigogi na EDM na graphite da jan ƙarfe ya bambanta sosai.

Siffofin EDM sun haɗa da halin yanzu, faɗin bugun jini, ratar bugun jini da polarity.

Mai zuwa yana bayyana tushen amfani da hankali na waɗannan manyan sigogi.

A halin yanzu yawa na graphite lantarki ne gaba ɗaya 10 ~ 12 A/cm2, ya fi girma fiye da na jan karfe lantarki. Saboda haka, a cikin kewayon halin yanzu da aka ba da izini a cikin yankin da ya dace, ana zaɓar mafi girma na halin yanzu, saurin sarrafa saurin fitarwar graphite zai kasance, ƙaramar asarar wutar lantarki za ta kasance, amma ƙarancin ƙasa zai yi kauri.

Mafi girma girman bugun bugun jini shine, ƙananan asarar lantarki za ta kasance.

Duk da haka, girman bugun bugun jini zai sa kwanciyar hankali aiki ya fi muni, da saurin sarrafawa a hankali da ƙasa.

Domin tabbatar da ƙarancin lantarki asara a lokacin m machining, in mun gwada da babban bugun jini nisa yawanci amfani, wanda zai iya yadda ya kamata gane low asara machining na graphite lantarki lokacin da darajar ne tsakanin 100 da 300 US.

Domin samun kyakkyawan farfajiya da ingantaccen tasirin fitarwa, ya kamata a zaɓi ƙaramin faɗin bugun jini.

Gabaɗaya, faɗin bugun bugun jini na graphite electrode shine kusan 40% ƙasa da na jan ƙarfe na jan ƙarfe

Tazarar bugun bugun jini ya fi shafar saurin injin fitarwa da kwanciyar hankali na inji. Mafi girman ƙimar, mafi kyawun kwanciyar hankali na injina zai kasance, wanda ke taimakawa don samun ingantaccen daidaituwar ƙasa, amma za a rage saurin injin ɗin.

A karkashin yanayin tabbatar da kwanciyar hankali na sarrafawa, ana iya samun ingantaccen aiki mafi girma ta hanyar zabar ƙaramin ɗigon bugun jini, amma lokacin da yanayin fitarwa ba shi da kwanciyar hankali, ana iya samun ingantaccen aiki mafi girma ta hanyar zaɓar babban gibin bugun jini.

A graphite electrode machining machining, bugun jini gap da bugun jini nisa yawanci saita a 1: 1, yayin da jan karfe electrode machining, bugun jini tazari da bugun jini nisa yawanci saita a 1:3.

Ƙarƙashin ingantaccen aikin graphite, madaidaicin rabo tsakanin tazarar bugun jini da faɗin bugun bugun jini za'a iya daidaita shi zuwa 2:3.

A cikin yanayin ƙananan ƙwanƙwasa bugun jini, yana da fa'ida don samar da murfin rufewa a kan farfajiyar lantarki, wanda ke taimakawa wajen rage asarar wutar lantarki.

Zaɓin zaɓi na polarity na graphite electrode a cikin EDM daidai yake da na jan ƙarfe na jan ƙarfe.

Dangane da tasirin polarity na EDM, ana amfani da mashin ingantacciyar polarity yawanci lokacin da machining mutu karfe, wato, electrode yana da alaƙa da ingantacciyar sandar wutar lantarki, kuma ana haɗa kayan aikin zuwa madaidaicin sandar wutar lantarki.

Yin amfani da babban halin yanzu da faɗin bugun bugun jini, zaɓar ingantacciyar mashin ɗin polarity na iya cimma asarar wutar lantarki mai ƙarancin gaske. Idan polarity ba daidai ba ne, asarar lantarki za ta zama babba sosai.

Sai kawai lokacin da ake buƙatar daɗaɗɗen shimfidar ƙasa da VDI18 (Ra0.8 m) kuma girman bugun jini yana da ƙanƙanta sosai, ana amfani da sarrafa polarity mara kyau don samun ingantaccen inganci, amma asarar wutar lantarki yana da girma.

Yanzu kayan aikin injin CNC edM suna sanye da sigogin injin fitarwa na graphite.

Yin amfani da sigogi na lantarki yana da hankali kuma ana iya haifar da shi ta atomatik ta tsarin ƙwararrun kayan aikin injin.

Gabaɗaya, injin na iya saita ingantattun sigogin sarrafawa ta zaɓar nau'in abu, nau'in aikace-aikacen, ƙimar ƙarancin ƙasa da shigar da yankin sarrafawa, zurfin sarrafawa, sikelin girman lantarki, da sauransu yayin shirye-shirye.

Saita don graphite lantarki na edm inji kayan aiki library arziki aiki sigogi, da kayan irin za a iya zabar a cikin m graphite, graphite, graphite dace da wani iri-iri na workpiece abu, don rarraba aikace-aikace irin ga misali, zurfin tsagi, kaifi batu, babban yanki, babban rami, kamar lafiya, kuma samar da low hasãra, misali, high dace da aiki da yawa zabi na aiki.

5.Kammalawa

Sabuwar graphite lantarki abu yana da daraja popularizing vigorously da abũbuwan amfãni za a hankali gane da yarda da gida mold masana'antu masana'antu.

Daidaitaccen zaɓi na kayan lantarki na graphite da haɓaka hanyoyin haɗin gwiwar fasaha masu alaƙa za su kawo fa'ida mai inganci, inganci da ƙarancin farashi ga masana'antun masana'anta.

Lokacin aikawa: Dec-04-2020